Piston-powered airplanes subject pilot and passengers to unpleasant vibration. Battery-electric airplanes have minimal range.

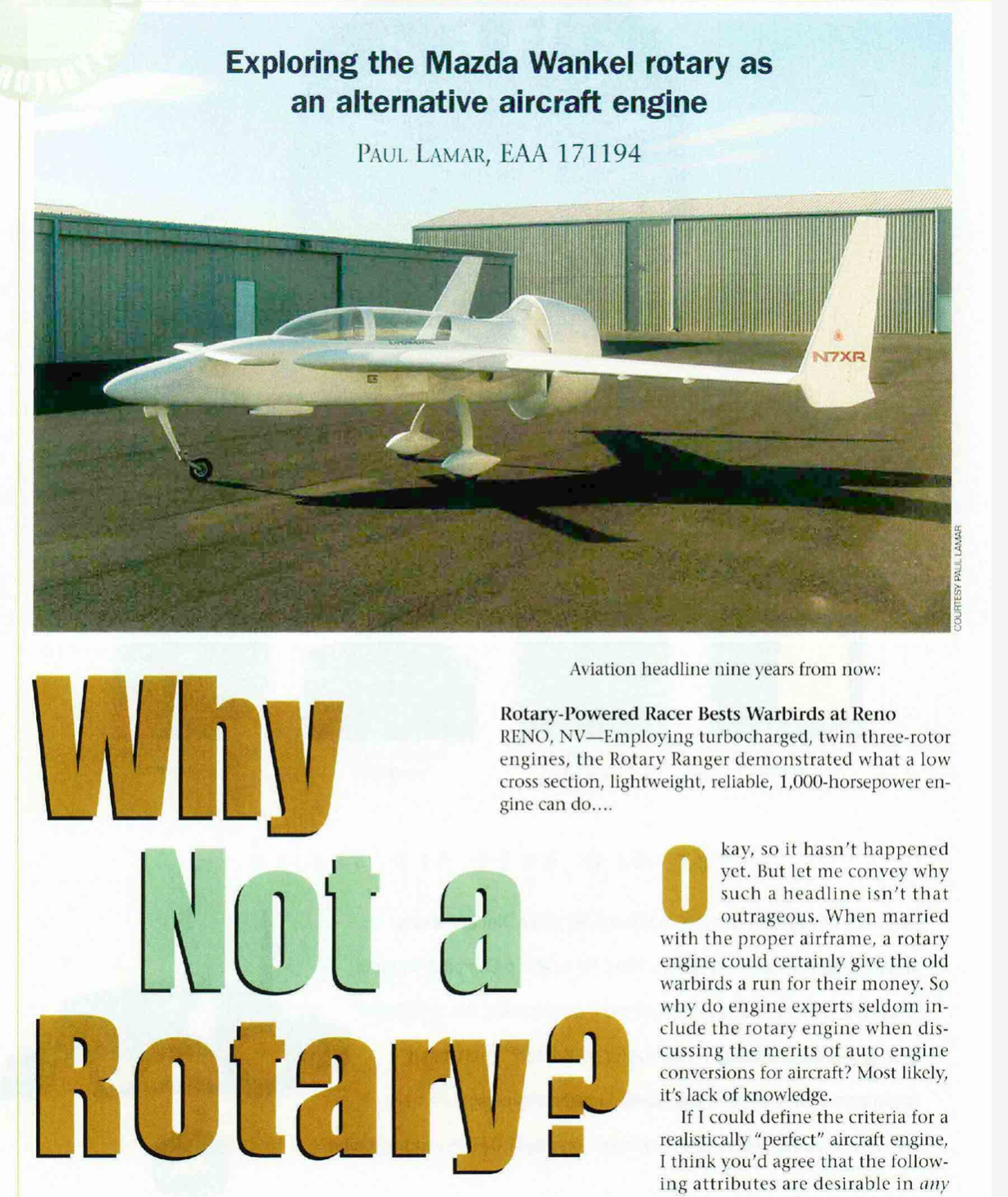

There have been some successful applications of Wankel rotary engines in aircraft. The homebuilt folks have had some success with Mazda RX-7/RX-8 engines. Here’s an article from EAA’s Sport Aviation in 2002:

While incredibly reliable in automotive use, car engines haven’t done well running at high power settings all day every day in airplanes. The aviation-specific rotary engines thus far, such as Diamond’s AE50R, are low power engines designed for self-launching gliders and UAVs.

What if the smooth rotary engine were used to generate electricity buffered through a battery pack? Then it wouldn’t matter if the engine failed more often than 1930s-style Continental and Lycoming piston engines. An engine failure would mean using a 20-minute battery reserve to land. Is there a mass-market low-cost battery+Wankel combination available? Yes! From “The Hybrid Wankel Rotary-Powered Mazda MX-30 R-EV Is Finally Here. Here’s How It Works” (Autopian, January 2023):

For starters, the engine doesn’t drive the wheels. It only serves as a generator connected to a motor/generator unit to send power to the battery pack. The battery pack then provides juice to an electric motor which powers the wheels. This means that despite burning gasoline, the MX-30 R-EV should theoretically have the seamless power delivery of an EV, and it should be able to keep the Wankel engine at its “sweet spot” for efficiency for a significant portion of its on-time.

As for deeper details on that rotary engine, there’s the presence of direct injection, something never attempted before on a production rotary engine. The side housings are aluminum and coated with plasma for low weight and friction management respectively, all while being just 80 mm wide. For the sake of longevity, the apex seals are 25 percent wider than the ones on an RX-8’s RENESIS engine, clocking in at 2.5 mm. The result is 73.7 horsepower from just 830 cc of displacement. Curiously, although rotary engines love to rev, Mazda claims that peak power hits at just 4,700 RPM. That might sound weird for a high-revving Wankel, but it should translate to very low noise.

At 214 pounds, it looks like this engine is fairly heavy for its horsepower (a little heavier than an 80 hp aluminum piston engine), but given the high efficiency of electric drive maybe this would still work out well for a 2-seater.

Readers: Where’s the flaw in this path toward aircraft powered by a mass-market powertrain?

Related:

- “New four-chamber rotary engine could supplant Wankel and piston engines for UAV applications” (SAE, 2018); based on the company’s web site, it looks as though no progress has been made in the last 5 years (blame coronapanic?)

Here is a more in depth article about the rotary long ez. http://stargazer2006.online.fr/derivatives/pages/duckt.htm Not mentioned here is the plane was sold and required with a 1930’s technology lycoming o-320 (which the plane was designed for). While it looks cool and did fly I don’t think we could call this a “successful application” by any stretch. Where’s the flaw in this path toward aircraft powered by a mass-market powertrain? Rotary engines are not more reliable than a 1930’s lycoming. Adding the complexity of some sort of hybrid system just makes the contraption less efficient/heavier/more expensive etc etc. By far the most successful auto engine in an airplane is the Subaru 4 cylinder opposed engine almost identical to the configuration of a lycoming but needs heavy water cooling and a prop reduction gear box nobody has really figured out. The future for general aviation engines in my opinions are the jet-a variety that all spin in the same direction. Take your pick between a small turbo prop or jet.

Thanks for that. It sounds as though the airplane flew quite a bit in reliance on the Mazda engine! At least 500 hours? (My friend who recently bought a factory-new Cirrus SR22 ($1 million down the toilet!) didn’t make it to 50 hours before being grounded by the Continental AD!)

The only reason there was no ADs against the long ez is that experimental planes can’t get ADs! In fact experimental planes are not even considered “airworthy”. It is true he got maybe 500 hours in the plane in that suboptimal configuration but it was never reliable and each flight was a test flight. One of the real big problems with the rotary engine is the metal seals wear out very quickly. Here is an interesting video of the latest rotary engine ever. https://www.youtube.com/watch?v=sXOffbLH_I0

The better economy of hybrid powerplants in automotive applications comes from regenerative braking, reduction of time IC engine spends at low power, and reducing the need for higher torque at low RPMs (which is the real reason why autos need hundred(s) of HPs). Unlike IC engines, electric motors can produce full torque from 0 RPM

None of that applies or useful for aircraft engines, which spend most of their air time at a steady 50-80% load in cruise (except maybe school trainers…) That load profile makes hybrids LESS efficient than direct-to-prop IC engines.

Rotery engines are interesting but normally run at too high RPMs for props requiring reduction gear box which both adds mass and reduces TBO. (Prop RPM is limited by lunear speed of tips apporoaching speed of sound; the amount of air moved by a prop is proportional to square of its diameter; thus to make a more powerful prop you inrease its size while reducing RPM – all the way to helicopter rotors).

(Jet engines also try avoid supersonic flows inside the engines, using both propertis of ducted fans and dependency of speed of sound on temperature.)

You cannot convince me that the electric part of a hybrid powertrain could not be made more reliable than an aircraft piston engine. Also: an electric engine without an attachment to the rotary part would almost certainly not need a reducing gear. Electric motors are well-known for producing full torque at low speeds. There are also hybrid electric concepts with traditional aircraft engines, capitalizing on the idea that aircraft engines are generally not run at full power for extended periods, so it could possibly be set up to “overdraw” the battery on takeoff and climb, then charge either on the ground or in cruise.

No matter how few batteries you place, it will be worse power density than gasoline. Also, now you need the weight of two motors. But arguably if there is a real safety enhancement maybe it is worth the performance cost? It would seem that a fully charged battery with electric motor is less likely to fail on takeoff (before gaining alt) too.

Dave: “weight of two motors”? The rotary engine in the Mazda car and in my scheme is only a generator. It runs at just one speed to charge the batteries. You’re right that the batteries will compromise performance compared to hooking a combustion engine to a propeller. But the battery buffer is a huge safety advantage, I think, and the drivetrain from the car is essentially free by aviation standards.

In a serial-electric hybrid scheme, motor #1 is the electric motor turning the prop and motor #2 would be your Wankel generator. Then you have the weight of the batteries plus the weight of the fuel. Clearly, both motors plus batteries will weigh more than a fossil Lycoming by itself.

A Lycoming O-200 powering a Cessna 150 has a dry weight of 170 lbs. My calculation is that the weight of the batteries for a 20 minute flight at 100 horsepower with 200 Wh/kg energy density is about 274 lbs. CATL claims they can do 500 Wh/kg which would get you down to 110 lbs (assuming no energy conversion loss). I found a Czech electric motor (REB-90) that weighs 50 lbs

and puts out about 100 hp continuous. So maybe with a fantasy CATL pack and the REB-90 you actually beat the weight of a Lycoming? If I could actually buy those 500 Wh/kg batteries I think I would just stack them up in a plane and forget the Wankel nonsense.

But back to your question – would the hybrid be more reliable? Intriguing if true.

To prove your reliability/safety idea, it seems those pure electric Pipistrel trainers would be a good model. I wonder if anyone is collecting detailed failure data on them?

Dave: The O-200 is certainly a proven technology, but even on its best day it will rattle the teeth out of the aircraft occupants. Part of my Mazda hybrid dream is turbine smoothness at a piston price.

You know we’re in another dot com boom when the wankel powered airplanes become a thing again. The Moller sky car was the big thing in the days before SPACs & quantitative easing. It must have given wankel a bad name, but the extra step of gasoline to electricity was already tried for quad copters & proved to be too another failure point.

> Where’s the flaw in this path toward aircraft powered by a mass-market powertrain?

It adds multiple potential points of failure: battery, battery charger, battery controller, electric motor, electrical connections, etc.

Diamond DA62 uses a “mass-market powertrain”, based on a Mercedes diesel engine. They recently found problems with its piston rings, and reduced the TBO from 2,000 to 1,000 hours.

I can’t find anything about this on the Interweb. Do you have a source for the new regulation on the Austro Engine AE 330? I do see that Diamond is selling a jet-style power-by-the-hour program. https://www.diamondaircraft.com/en/austro-engine/e4-series/overview/ is suspiciously free of any TBO number!

@philg: I can’t find where it read it either (maybe I’ve got long-covid brain fog?), so please delete the above comment.

The only thing worse than Long COVID for memory is Long Monkeypox. I think you’re probably right that they’ve gone back and forth with various TBOs for these engine/transmission combinations. The fact that the web site doesn’t provide the current TBO is suggestive! (I guess with their power-by-the-hour program, the customer doesn’t have to care too much, though the downtime could be significant.)

update 2.0 – found the source. Clarifying prev comment: its not TBO, and its only a limited number of engines:

“MSB-E4-039 … Austro Engine has identified an issue with a limited number of Austro E4 Engines that can be rectified by the applicable Mandatory Service Bulletin”

https://www.diamondaircraft.com/en/service-and-support/msb-e-4-039

“MSB-E4-039/1 24.04.23 … [for a subset of engines] At 1,000 flight hours: replace pistons, piston rings, and con-rods OR replace engine core”

https://partners.diamondaircraft.com/s/contentdocument/0692p00000V1TXCAA3

Rotary engines have long thin combustion chambers that are inherently thermodynamically inefficient.

What to do about battery fires?

https://en.wikipedia.org/wiki/Plug-in_electric_vehicle_fire_incidents

In a car, you have a couple of seconds to get out.

Hey, Toucan Sam: In your comment on May 10, 2023 at 1:32 pm, you said: “…Experimental planes are not even considered ‘airworthy’.”

Please explain to me how my experimental amateur-built Glasair Sportsman has an Airworthiness Certificate.

You have a “special airworthiness certificate”. Every year you do a “condition inspection” which is supposed to conclude that your airplane is in “condition for safe operation.” If you had a type certificated aircraft you would have a normal “airworthiness certificate”. You would then need to do an “annual inspection” which would make sure your airplane complies with its type certificate. If it does comply with a type certificate the FAA calls that “airworthy”. It’s all spelled out in FAR Part 21.183(a), (b), and (c).

Have you seen this project?

https://corsairpower.com/

(adapting automotive V8)