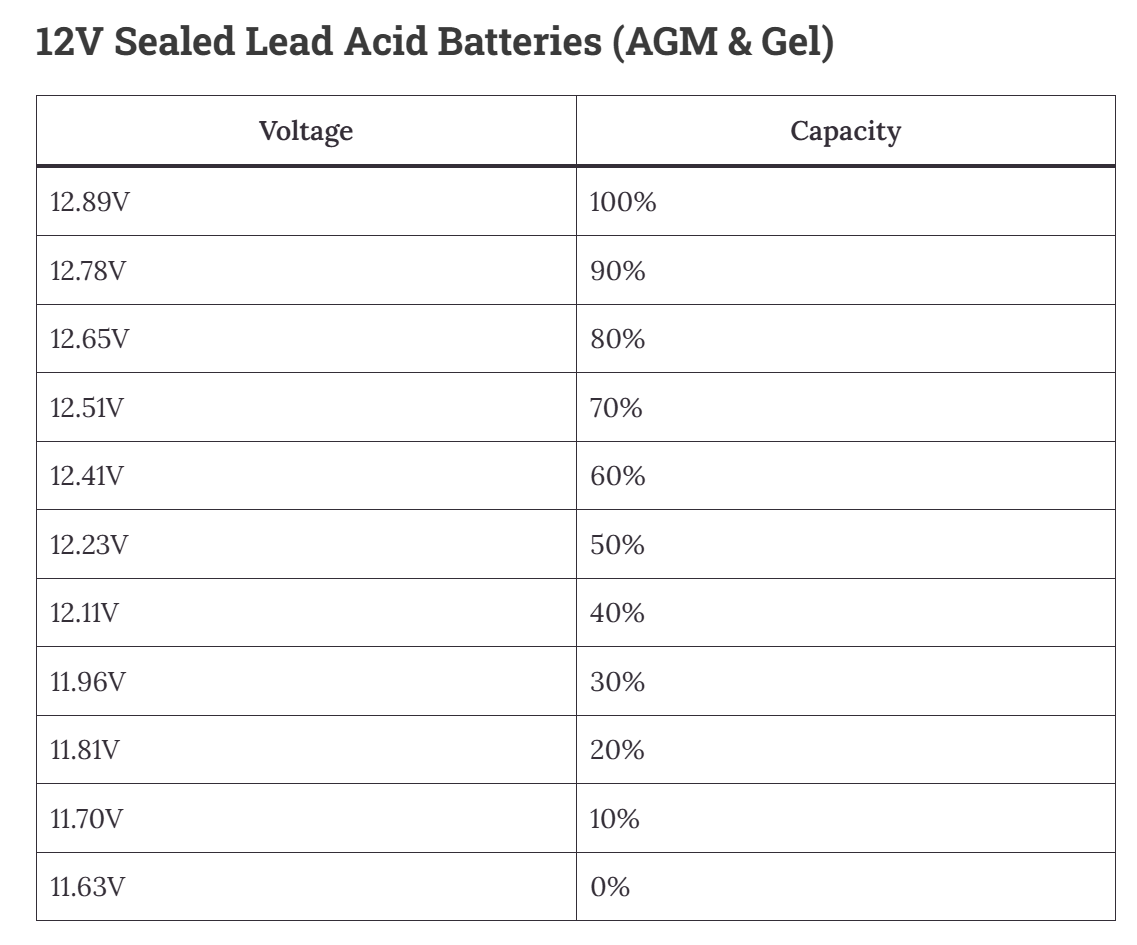

I’m not sure what caused our rented-from-Sixt Mercedes E 300de to fail and refuse to start even with a jump, but I am suspecting 12V battery health. The battery measured 12V on the tow truck guy’s multimeter, which sounds good for a 12V battery, but the chart below (source) says 12.4 is more of a practical resting minimum:

Today’s question is why cars don’t all come standard with battery health warnings, similar to the warnings regarding when it is time to change the oil.

- The car knows the battery voltage before start and after engine/generator shutdown.

- The car knows how long the last trip was (i.e., duration of most recent charge).

- The car knows how long it was sitting since the last trip (i.e., expected voltage drop from self-discharge).

- The car knows roughly how hot it has been (maybe use the temperature at startup for this and apply it to the sitting period and, if refinement is desired, tweak for the time of day).

If the car sees consistently lower-than-expected voltages, shouldn’t it flash a “replace battery ASAP” message to the owner?

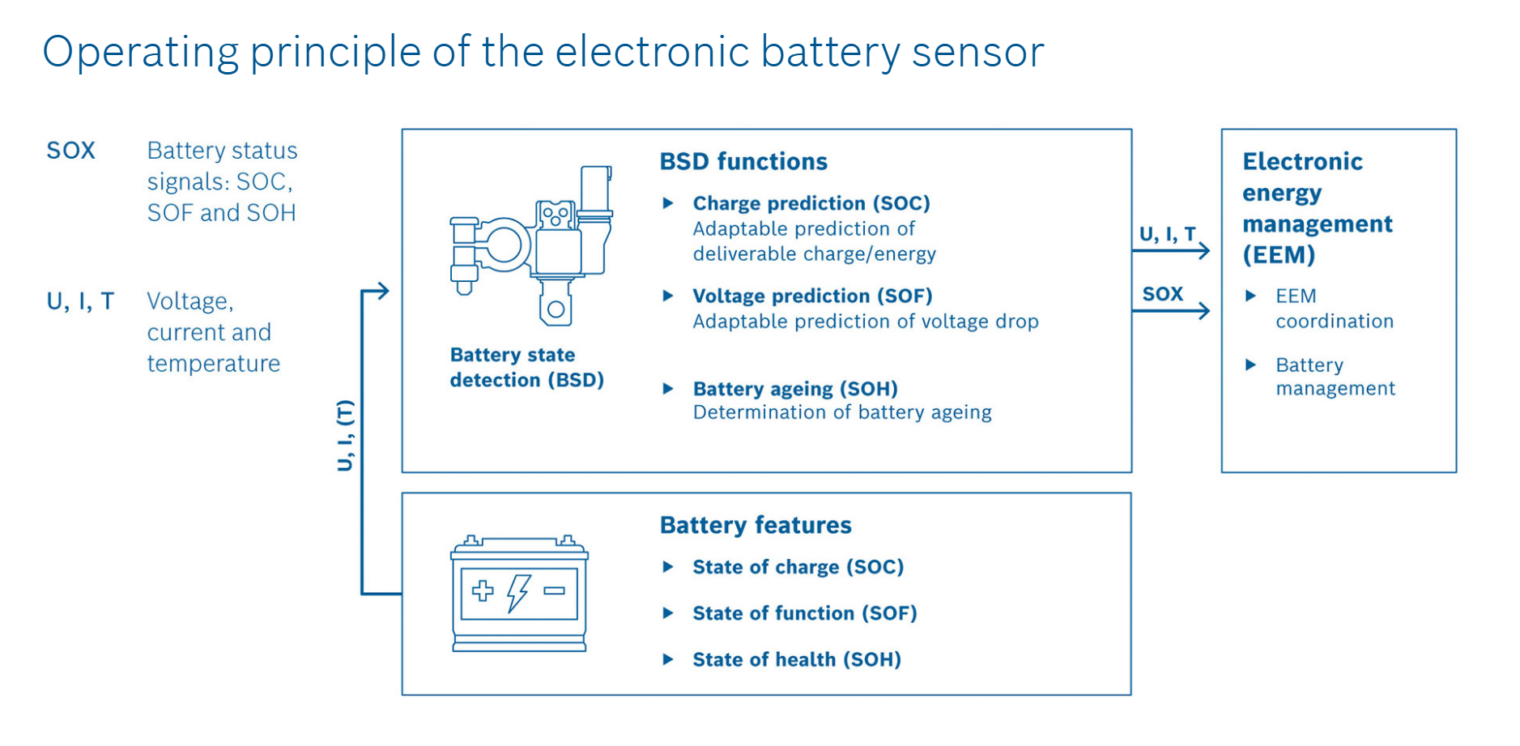

Bosch seems to have a product that tries to do this, but I haven’t seen it in action:

I’m not sure why the Bosch hardware is needed when the car already has voltage and outside temperature sensors, plus a clock.

Our dead Mercedes displayed a “low battery” warning, but only after the total failure. It also said “towing not permitted” (what is the alternative if the car won’t start?) and “See Owner’s Manual” (we weren’t supplied with one):

Ford says that an owner should come to the dealership after he/she/ze/they “Constantly experience charging or electrical system problems” or “Experience trouble or difficulty getting your engine to start”. Why is this the best that modern electronics and software can do?

Mu guess because car battery is rechargeable from engine at run time and it can not be certainly forecasted that when battery is cooled (or heated back to garage temperature in the winter) it will not charge again. I always drive with portable jump-start battery and jumper cables. I had to jump-start my cars maybe at most 5 times in 30 years, all during cold winters after prolonged outside parking. If you rental could not be jump-started, it probably had more profound issues then low charge on 12 V battery.

The blog continues the reputation of all expensive stuff being lemons. Someone’s got to pay for the Audis, Teslas, Mercedii, iphones, airplanes, $3 million starter homes, $1 million refrigerators, $1 million stoves to make the rest of us feel better about being poor.

lion: The Mercedes rental was about $70/day. If you add in their charges for tow trucks and a wheel scratch and loss of use from the wheel scratch and the admin fee from the wheel scratch it still works out to only about $100/day. Considering that I’ve paid over $100/day in the U.S. for a Camry or similar, I wouldn’t call that “expensive”.

The check engine light has been on for over ten years in my ’01 Ford Taurus. Every dash light in my ’08 Honda Ridgeline has been on for the past six years. The Honda dealer can’t figure it out and I’ve given up. Seems to run fine w/ just 70K miles on it. Still using a Honda-branded OEM battery for seven years.

It’s funny. My hybrid has (and needs) a 12v battery despite having a relatively massive high-voltage battery under the seats. It’s also been the least reliable component in the whole car, requiring replacement every 2 years or so. The computers which run the hybrid system can’t start without it and there’s no provision for charging it from the traction battery unless the hybrid system is running. Starting the computers requires very little voltage and current, but the car is utterly dependent on it. The usually amazing Toyota engineers deserve a wall-of-shame mention for this one.

There are good reasons for this from a car architecture. For safety reasons; the high voltage battery must be able to be isolated. To do that some separate computer must control the contacts and a battery must power it. This is the 12V battery. Tesla have innovated this into a relatively small LiIon 16V battery which is much more compact.

Having the 12V battery charged by the engine is natural architecturally and also consistent with the reason above.

In a different but slightly similar way; passenger jets have an APU (typically in tail cone) separate the to the ‘traction’ dual jet engines. Simplistically why do this? Just run one of the big engines? Because practical reasons.

12v batteries start engines and then are recharged by that engine. More starts and less engine run-time to recharge that battery wear out the battery faster. Hybrids by design have more starts and less engine run-time, so the 12v batteries are going to wear out faster in a hybrid.

You’ll see this also to a lesser degree (more starts but similar engine run-time) with the engine auto-stop/start that tries to save gas at traffic lights, which is why I disable the start/stop function on my vehicles. It’s bad for the starter but worse for the 12v battery.

Also, I get about 7 years out of most of my 12v vehicle batteries by plugging them into a battery maintainer about once a month.

Maybe after car makers have enough telemetry data analyzed by enough AI, they will have a better method than a calendar and “risk taker” profile. For now, if cautious, replace battery after 3 years; if cheap or high risk taker, replace after 4 years, or when battery won’t start car.

I think that voltage is not a good predictor of battery failure. The relative voltage difference between a 30% and a 100% battery is 7% according to the chart (11.96 and 12.89V). Moreover I think the chart would not be applicable across different manufacturers. Also manufacturing process variations may lead to imprecision w.r.t. the voltage – capacity relation.

A significantly better predictor, in my opinion, would be the internal resistance of the battery. To calculate it one would need to measure the voltage when idle and the voltage during the short interval in which the battery powers the engine. It should be doable by the car hardware so, indeed, why don’t they implement it?