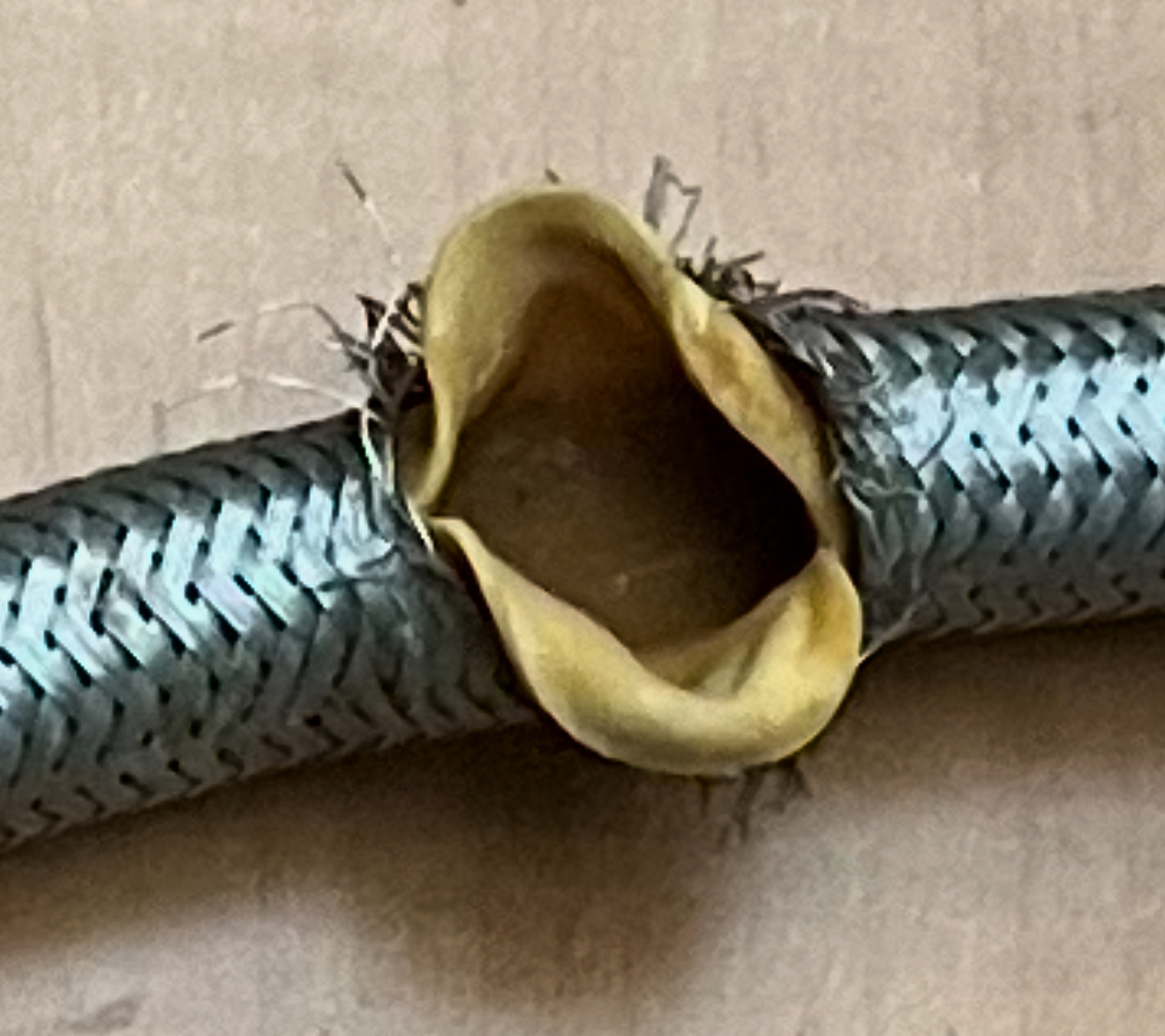

One of our neighbors recently suffered a massive flood in their house due to a burst sink supply hose:

Readers: What material do you think we’re looking at here? A vinyl or rubber inside pipe surrounded by braided stainless steel?

All of our houses in this sub-development (within Abacoa) are 20 years old so it is possible that this supply hose had been waiting to fail for 20 years. This plumbing company says to replace the supply lines everywhere in the house every ten years, but also implies that five years is the correct interval:

The general rule of thumb is to replace all your supply line hoses every 5 years as a preventative measure to protect your home against any potential leaks. But since braided supply lines have a rubber core, we recommend that they can be replaced every 10 years.

The Fluidmaster Pro supply lines have a 10-year warranty, which presumably means that replacing after 7-8 years would be smart. A set of two is less than $20, I think, so it wouldn’t cost a lot to hit all of the sinks and toilets in a house.

Does anyone reading this have a Moen Flo AI overlord water shutoff device in his/her/zir/their home? If so, I would love to hear about it in the comments. It seems as though it would have potential to generate hassles, e.g., Family Member A is in the house taking a shower while Family Member B is outside topping off the pool, which looks to the Flo like a one-hour massive leak (it is possible to tell the Flo to sleep for a bit while one is doing something unusual with water). The Flo can be installed outdoors so long as there is an electric outlet nearby and it can latch onto 2.4 GHz WiFi (I think we can meet those requirements).

Another potential source of paranoia is erosion of copper supply lines by hot water recirculation. Apparently the pump has to be sized exactly right, which involves a lot of calculation (example). In an innumerate society such as the U.S., the inevitable result is a lot of houses being built with big pumps thrown at the recirculation system.

I think a WiFi/Zigbee/whatever leak detector is a better idea. I used to have some in my old house, and on two occasions they detected potential flood issues: a dishwasher leak and a a leaking water heater in the basement.

E.g.: https://shorturl.at/B2z3q

Now I sort of do not care.

Thanks, Ivan. I already have a bunch of Govee sensors for leaks in various places. https://amzn.to/3UsUV5e seems to be the latest version. They do work well, but what if we’re not home and it happens in the middle of the night and the phone is on “sleep mode” and, even if we did hear the alert, can’t wake up a neighbor?

Maybe the lion kingdom will stick to renting.

Replace not just the hoses, but all the valves too. The floor + walls in my downstairs bathroom was ruined by a leaking valve that went unnoticed for a few days (it’s a room that is rarely used).

Anon: I’m surprised to hear you say that the valves leaked so dramatically. My model of these plumbing shutoff valves is that they fail by dripping not by pouring water out!

My mother’s whole house was ruined by a plumbing leak, that happened while they were in Hawaii for a month. The leak on the upstairs bathroom seeped through the ceiling, down onto the main floor. The insurance company decided it was a totalled.

A scary ‘hairy’ hose for Halloween!

We do failure analysis on this type of hose all the time. The ‘stainless’ steel is often not a high quality grade and corrodes. Once the metal outer braid fails, the rubber liner is not strong enough to hold the pressure and it ruptures. The ‘hairy’ moniker is because you can usually see individtual strands failing and poking out prior to catastrophic failure. As you can see in your picture, there are many other places on the hose were it is discoloured (darker grey, powdery white, or a rust colour) and I can even see a few strands of wire protruding. A ticking time bomb. See below from one of my colleagues.

https://www.hawkins.biz/insight/flexible-braided-hoses-down-to-the-wire/

What to do about it? Yes, you could replace every X years if they are easy to access. However, a ‘good’ hose should last a very long time. A close visual inspection probably gets you 99% of the way there. If there is no discoloration, broken braids, etc. then leave it be. Of course, if your bathroom is above a room with priceless artwork below, then maybe not.

The various water detection sensors seem good in concept, but rarely are situated exactly where the water goes. So there is no perfect assurance that you will be made aware of the leak. I wouldn’t pay a massive amount for them, but as you already have a few sensors around that is fine. Better to have some coverage than none.

The other type of system with a flow sensor, monitoring device, and shut-off solenoid valve on the water supply are definitely not ‘AI’, but instead likely a rudimentary algorithm (if flow is greater than X, for duration Y, then shut off). These also have a minimum detection threashold, so they don’t pick up weeping or dripping leaks on concealed pipework in your walls.

Your pool is any exception, but most people probably don’t run water for more than 1 or 1.5 hours (the systems I have seen are configurable in this regard, even up to 6 hours of water flow or more, before shutting the water off). If you can exclude the pool, then this could be helpful if a hose bursts when you are out or away. Less damage from an hour of water, than from a whole 8-10 hour day or longer. Some systems also shut off the flow if there has been no usage for X number of days, so it acts to isolate the water when you are on holiday (you have to turn it back on upon return).

Good luck. My house is 23 years old and I have replaced one hose so far… but I take good look whenever I happen to be in the cupboard under the sink. I haven’t installed a leak detection system, but one day I might if the cost were moderate.

I have had the Moen (actually, the pre-Moen version) in three houses. In all cases they eventually failed due to internal corrosion. They could still detect pressure and could run the pressure decay leak test, but they could no longer detect flow and so could not detect a leak in real time. But also, in all cases, in the several years they all worked prior to the impeller freezing up, they saved us from significant water leaks. They also taught my son-in-law to take shorter showers at our house and not try to personally empty the hot water tank each time he took a shower.

> They also taught my son-in-law to take shorter showers at our house and not try to personally empty the hot water tank each time he took a shower.

Today’s generation! 🙂 Same with my son-in-law and my kids. For me, a shower is a 3-4 minute thing. For them, 10+ minutes. They will brush their teeth while taking a shower! And with the new showerheads, that spit out less water, 15-20 minutes shower is common.

Btw, according to #Science you do your body harm if you take long showers and over clean.

I’ve read many similar stories about failed impellers in the Moen. I’ve been looking into this unit which doesn’t have moving parts in the flow sensor.

https://phyn.com

I had one of the Moen Flow devices installed in a home we owned a few years ago. Just to keep it brief, I found the telemetry from the device to be useful, basically peace of mind when we were away from the house (we split time between two properties). As I recall, part of their pitch is that the device learns your use patterns to help reduce false alarms. In our case, we had it trigger a few times due to our unusual use case (farm property, filling horse troughs, etc). I’ve generally soured on home automation over time – it just creates technical debt with having to maintain infrastructure, deal with failed startups going out of business, and so on.

I would echo the advice another commenter offered – we’ve owned quite a few houses over the last 15 years, and generally I got into the habit of buying a couple days each of plumber, electrician, etc time to perform proactive replacement. With plumbing, replace all the valves, usually swapping out gate valves for ball valves (personal preference), any suspect pipe, faucets, under sink drain pipes, etc. Replace the electrical panels (you haven’t lived until you find a semi-melted bus bar in a panel, or frozen-closed breakers). This sort of proactive work costs a lot more than the Moen, but I’d rather prevent a leak than detect. Also, placement of the Moen within the system determines how much risk you take off the table – in our case, it had to be down steam of the water conditioning systems, which left me uneasy that the water conditioning systems would leak undetected. But again, the telemetry was useful to me.

Our current house does not have a Moen installed. Yet. I’m on the fence at this point. If you’re into being the local IT guy, then I’d say go for it. Personally, I’m over the tech-bandaid phase of home ownership, and generally prefer one-and-done infrastructure replacement. All the usual caveats apply about finding skilled tradesmen, yada. Finding plumbers willing to work for an entire day is my current nightmare 🙂 Seems like I have to play plumbers-helper when the guy is here.

We have a part time home that relies on cisterns for water. During one absence, the 74 year old yard man absentmindedly left the water pump energized (chain link one) and a hose bib on (chain link two). The attached garden hose burst and the largest cistern was drained, after which the impeller on the dry running pump failed. We installed the Moen to guard against this in the future. There are minor issues with misidentifying certain loads as leaks, but the app interface and automated phone calls allow us to keep things balanced. We also place suction on the smallest cistern when we leave the home as an additional safeguard.

I have known dozens of homeowners for decades and I have never once heard of anyone preemptively replacing a supply line like that unless it was leaking or damaged. (Perhaps when kitchens or bathrooms are renovated or appliances are replaced).

SuperMike: Now that these supply lines are, no doubt, down to less than $1 each when a faucet manufacturer purchases them in quantity, there is probably more risk of failure than in a house built and equipped in the BC years (“Before China”).

I agree with SuperMike.

When I was more paranoid about this sort of things, I just shut off the main valve whenever we left the house for more than a day or two, especially in winter.

Besides, in my current house, it looks like all piping is PEX, including leads to sinks and toilets \, so not much danger of copper corrosion.

What breaks from time time is cheap plastic local shut off valves the builder put in. As the result, they get into the self induced shut off state. So, I replaced those, perhaps 3 or four total of those during last five years

Preventively replacing all shut off valves seem rather an overkill. What about pipes in the walls ? Would it make sense to replace those as well every 5-10 years?

A scary ‘hairy’ hose for Halloween. This is a well known type of failure, associated with corosion of the stainless steel braid. Once the braid fails, the rubber/plastic liner is unable to withstand the pressure and ruptures.

This is caused by inexpensive grades of stainless steel being substituted for a higher quality specification (as would be found in aerospace or motorsports hoses). If you zoom in on the picture, you can see broken braids sticking out (‘hairy’) and discolouration (grey, white, or brownish rust). Thus, the incident hose was a ticking time bomb, as was the companion hose in the picture.

What to do about it? Inspect them once in a while, and if you see any signs of decay, replace immediately. Otherwise they are probably fine to remain in service, as a high quality hose will last for a very long time. I live in a 23 year old house and have replaced only one hose so far. That being said, probably best to put new ones in when a tap is replaced, during renovations, or if there are valuable items in the room below that can’t get wet. As has been mentioned above, the new hose may be lower quality than a good one that has been around for a while. However, eventually, even the liner will decay, so you probably don’t want 30-40 year flexible hoses regardless of the stainless quality.

As a side note, I am not sure what happened to my prior similar comment? Lost in moderation perhaps.

Previous comment was flagged as spam by our robot overlords!

In relation to paranoia about the recirculating hot water erosion issue, the fix for a house already built is simple.

You measure the pressure increase across the pump. Then reference the pump curve for that specific model. There will be only one flow rate for a given pressure across the pump. A quick calculation for the flow rate (volume) vs the diameter of pipe in your house will give you the flow velocity. Then you can consider if you are likely to experience erosion issues, normal recommendations are to stay below 0.5 to 1.0m/s on the hot water return. Erosion is well documented, but I don’t actually come across it very often….

The calculation is only more involved if you want to model the system prior to installing it, i.e. as a designer trying to get the pump right on the first try.

I deal with plumbers trying to fix these type of issues and they give me incredulous looks when I ask for the pressure reading across the pump…. It it is all easier if there are any fittings (drain ports, etc.) nearby that you can access to take the pressure readings. If you are that lucky, then you don’t have to disturb any of the pipework to gain assurance that all is fine. If there is a bypass (to make sure there is some flow across the pump if the loop is valved off for some reason), then you may want to ensure the bypass is set how you would like it to be before taking the readings (typically just open a crack).

Thanks, Adrian. It looks like the existing pump is soldered in. I can’t see any fittings of any kind. There is a ball valve on what I think is the return line going into the pump. So I’d need a plumber to do any measurements and at that point it would probably make sense to replace it with one of the new smarter circ pumps that will, supposedly, automatically adjust their flow rate to the minimum necessary.

I have what I think are all of the original blueprints for the house that were filed with the town 20 years ago. There is a drawing for the sewer pipes and vents, though it doesn’t show where exactly the pipes are within the house. There is no drawing that I can find for the plumbing in general! I have no idea where the hot water returns are coming from, for example (there is a far-away primary bedroom (not “master”!) and there are a couple of bathrooms upstairs so for all of these bathrooms to have immediate hot water I think there would need to be 2 or 3 returns.

Yes, your situation with the lack of measurement points is common. Despite the warnings on the internet, I re-iterate that actual leaks from erosion are not that common, so there is a 99% chance (or better) that you are fine. The absence of drawings is also common, and is frustrating, especially if there are multiple returns with balancing valves, it hard to know what you have! For a first approach I would assume the simplest system.

There are other ways to take a big picture view. You can consult your pump manufacturer’s literature to see which one you have. If your pump is the smallest one in the series (and your hot water is fine), then perhaps rest easy. You can also call their technical support team to ask what they would recommend for a house your size.

Another back of the napkin cross-check is the flow and return temperture. If you take a temperature reading on the outflow from the top of your hot water cylinder, the returning temperature at your circulation pump where it goes back into the cylinder should be about 20F cooler. If the returning temp is almost the same as the flow, then your pump is too fast, if the difference is greater, then you could use more flow (caution here – plumbers do this and then whack on a huge pump!) There can also be issues with balancing valves, if any are installd for multiple returns – don’t worry about this in the first instance, unless a specific tap is cold.

You can take temperature measuements on copper pipes by taping on a thermocouple or thermometer with electrical tape and leaving it for a few minutes. If you have an infrared temperature gauge, you can apply black 3M electrical tape with a known emissivity (0.95) and get instant readings.

If you really do want to go with the smart pump as a preventative measure, I would still check your present pump curve and the flow and return temps so that you can at least get a replacement that is likely to be about right.

I’m going to take your advice and measure the return flow temp at least. We definitely don’t need more flow. The water is hot within a few seconds after turning on the shower that is farthest from the heater. The existing pump is a Grundfos UP15-18B5. It is available for $303 on Amazon right now, https://amzn.to/40uyPU3, and Supply House sells it for $323. https://www.supplyhouse.com/Grundfos-59896114-UP15-18B5-Bronze-Circulator-Pump-1-25-HP-115V

It’s 1/25th HP and 14.7 max GPM (882 gph, which seems like way too much!).

https://product-selection.grundfos.com/us/products/up-ups-series-100-north-america/up-15-b-n-north-america/up-15-18-b5-59896114?pumpsystemid=2505207087&tab=variant-curves

seems to be the authoritative page and it says that the “rated flow” is about 5 gpm. There is no speed control, right? So the flow rate falls down from the max due to the load experienced by the pump?

I wonder if this could be the original pump from 2003 when the house was built.

You are correct, there is no speed control on the pump you have. The pump does whatever it can against the dynamic head (friction from flow) in the system and then you get whatever flow the pump can produce, hence the single line on the curve.

Grundfos are a high-quality supplier which have been around for a long time. The pump you have could be original, and might even last for many more years.

As we do not know the pressure across the pump in your system, we can only guess at the flow rate. If we take Grundfoss’s duty point as a mid-point for discussion (4.92 gpm), by my quick calculation this is 1.6m/s for a 1/2-inch copper pipe (nominal ID of 13.8mm). This is more than recommended (0.5 to 1.0m/s), but not off the charts, so perhaps fine.

Perhaps reassuringly, yours is one of Grundfos’s smaller pumps. There is one smaller in the same series, the 15-10 (as below), but I would not rush out to make changes without any data on your system.

https://product-selection.grundfos.com/us/products/up-ups-series-100-north-america/up-15-b-n-north-america/up-15-10-b5-59896213?pumpsystemid=2507524381&tab=variant-curves

Grundfos also make three speed pumps, which gives you some adjustment – my quick survey of Grundfos’s offerings puts your present pump in the lowest flow range of the smallest models, so without more detailed knowledge of the Grundfos catalogue it is not possible to know if there is another one that would offer an improvement.

A quick search reveals other brands with infinitely variable speed control, as below. I do not know this brand to make a recommendation. It would be hard to argue against the Grundfos having lasted 20 years! But a variable speed control would let you turn the pump right down.

https://s3.amazonaws.com/s3.supplyhouse.com/product_files/Taco-006E3-Product-Overview.pdf

If you do get a smaller pump, or a variable speed one, then make sure your return temp is higher than 120F, so that legionella bacteria cannot survive in the system. For example, the water might leave your cylinder at 140F, and return at 120F.

At this point, I digress on water temperatures. As I have children, I would prefer my entire system to be below 45C (113F), so that serious burns are prevented. However, this is against health guidance. I am sure my parents turned the hot water cylinder down when we were kids. Did we play Russian roulette with bacteria, or is not as big of a risk as advertised? My present heating system cannot be turned any lower than 158F (presumably for this reason), which means I need a thermostatic mixing valve at every outlet…

Adrian: What about the HWR ALPHA pump from Grundfos? https://www.grundfos.com/us/learn/research-and-insights/it-s-time-to-work-smart-

It claims to figure everything out and then set itself at the correct speed. Of course, the reviews in https://www.supplyhouse.com/Grundfos-99906545-ALPHA-15-55-HWR-T-High-Efficiency-Circulator-Pump-115-Volt-w-Line-Cord are pretty bad and say that the AI doesn’t work.

I didn’t realize that all of my pre-Florida life I was risking death via Legionella and similar bacteria! We didn’t have recirc in our Bethesda, Maryland 1950s builder-special house. We didn’t have recirc in any of the decayed older houses that I occupied during my long sojourn in Maskachusetts.

I’m probably over-thinking this. If the existing pump hasn’t caused any pinhole leaks in 21 years does that tell us that it is likely a reasonable choice? I’m hoping to have temperature measurements within a few days.

Hmm… Preliminary temperature measurements suggest that the temp might be too low and the flow rate too high. A pipe clamp thermocouple plugged into a multimeter shows about 103 degrees on the pipe returning into the recirc pump and also the pipe going out of the hot water heater. I’m sure that our hot water is hotter than 103, but probably not 120. I will do some more measuring!

ChatGPT says that there should be at least 5 degrees of temp drop and I’m not seeing that much.

———– wisdom from our future (current? Maybe ChatGPT has been running the country since Joe Biden went “full Biden”) overlord

In a well-designed hot water recirculating system, the temperature difference between the water leaving the heater and the water returning should ideally be small—usually around 5–10°F (about 2.5–5.5°C). This minimal drop helps ensure that hot water is readily available at taps and reduces energy loss.

Yes, you probably are overthinking this, but it can be satisfying to test your house and get everthing right.

I don’t have personal experience with the Grundfos Alpha pumps – I suspect they do what they say on the tin. However, this system does not need to be smart. The pump you have is limited by the winding resistance and impellor load and has worked flawlessly for 20 years. Will the Alpha? What will Grundfos Apps be in 20 years? It is cool that it can set itself up though. The only smart feature that might be nice is is a timer to turn it off at night, when you don’t need instant hot water.

Re measurements – are you measuring on bare copper pipe? You need good contact between the thermocouple and the pipe. Also the backing clamp should be in place long enough to come up to temperature – hopefully it is a bit insulating so that you are not including the air temp behind the probe? You can measure with a bare thermomcouple pressed onto (or taped) under some foam pipe insulation (which is hopefully on your pipes regardless).

If you don’t trust your instrument, you can check thermocouple calibration with a dunk in an ice bath for the low end and boiling water for the top end.

The hot water tank may also vary between a range of temps, i.e. it will call for heat and reach its maximum, then the temp will decay over time until the thermostat kicks in and it warms up again. It depends where in the cycle you are taking your measurements. You can time your measurements to be after a heating cycle – i.e. morning showers for everyone might empty the cylinder and trigger a demand for heat. You can then catch it at the peak after that.

If you are still not sure about the pipe exterior temperature vs water temperature, you can measure the hot water flow from what you think is the closest tap to the cylinder, this will give you the water temp inside the pipe, which you can compar to your reading.

I have looked at my notes for the last one I checked. This was a fancy 3 bedroom, 4 bathroom flat, plus kitchen. The system was big enough that pipe lengths would be similar to my 4 bedroom house (in the UK), so you can consider this in relation to your house (probably bigger in Florida?). The flow temp was 158F the return was 140F. The pump was a 3 speed Wilo, as below, on the curve for the lowest speed setting.

https://wilo.com/gb/en/Products/en/products-expertise/wilo-sb/sb-30?param10=%7B%22dutyPoint%22%3A%7B%22Head%22%3A%228.82%22,%22Flow%22%3A%222.5%22,%22StaticHead%22%3A0%7D,%22dutyChartOptions%22%3A%7B%22View%22%3A%22Product_DutyChart%22,%22VisibleParts%22%3A%5B%22HEAD%22%5D%7D,%22flowUnit%22%3A%22US%20g.p.m.%22,%22headUnit%22%3A%22ft%22,%22pressureUnit%22%3A%22kPa%22,%22headIsPressure%22%3Afalse%7D

I would not trust Chat GPT on the temperature differential. If you run your system with such a small drop, it is not energy efficient (as suggested). This is due to the high pumping speed and associated losses, as well as the ‘hot’ pipe running through your walls radiating out heat, which you then have to air condition away!

In old school non-recirculating systems, you intermittantly run hot water to the taps which kills the bacteria. You just have to wait a period for it to arrive. The ‘bad’ scenario is in recirculating systems is where you have a steady state region permanently at a temp which bacteria colonise and live forever (i.e. the hot return section of pipe that is coolest). Or a dead end leg of pipe that is stagnant and luke warm.

I am waiting for my kids to get older, but as a Science Fair project I want to test the bacteria load in my kitchen tap, right after a holiday when the water has been stagnant for weeks. Did you get sick from the return flight home, or from your first drink from tap. Hahaha…

I installed water hero 7 years ago. (https://waterheroinc.com/) You can set threshold for how long water flows before it will shut off main valve. I set it for 30 minutes for alarm and 45 minutes for shut off. My sprinkler schedule has 10 minutes gaps between zones, and runs at night. There are few flaws:

1. default settings for flow sensor are too sensitive. HVAC had EM interference with this device. Helpdesk could adjust sensitivity from central point that resolves this issue.

2. box needs hard reboot once or twice per year. There is no alarm when box is not accessible via Wi-Fi

Thanks, Victor. It doesn’t look as though it is trying to be as intelligent as Phyn or Flo.