Americans’ perception of inflation certainly seem to be higher than the official CPI numbers. Workers demand 30 percent raises (and get them, in California) when Pravda says that inflation has been less than 10 percent and is now down around 3 percent. Previously, I’ve wondered if part of that is due to delivery times stretching out into the next Ice Age: Is inflation already at 15-30 percent if we hold delivery time constant? The quoted price doesn’t go up more than 20 percent, but you might not get your refrigerator for a year or more (a Sub-Zero fridge that was formerly available in 7-10 days now takes 12-15 months). A Cirrus SR20 is priced at more than double what we paid for our 2005 SR20 from the factory, but delivery time is 2 years instead of 3 months. What’s the actual price of something that doesn’t exist?

After talking to HVAC contractors, a regular event here in Florida, I’m wondering if this is also partly due to repair parts shortages. A/C systems that were designed to last 12-14 years are being scrapped at 5 or 6 because essential parts (not as “essential” as marijuana in Maskachusetts or California, but required for cooling) are theoretically available, sometimes for free under warranty, but practically unavailable (lead times of 8-12 weeks, which is no solution at all in a South Florida house).

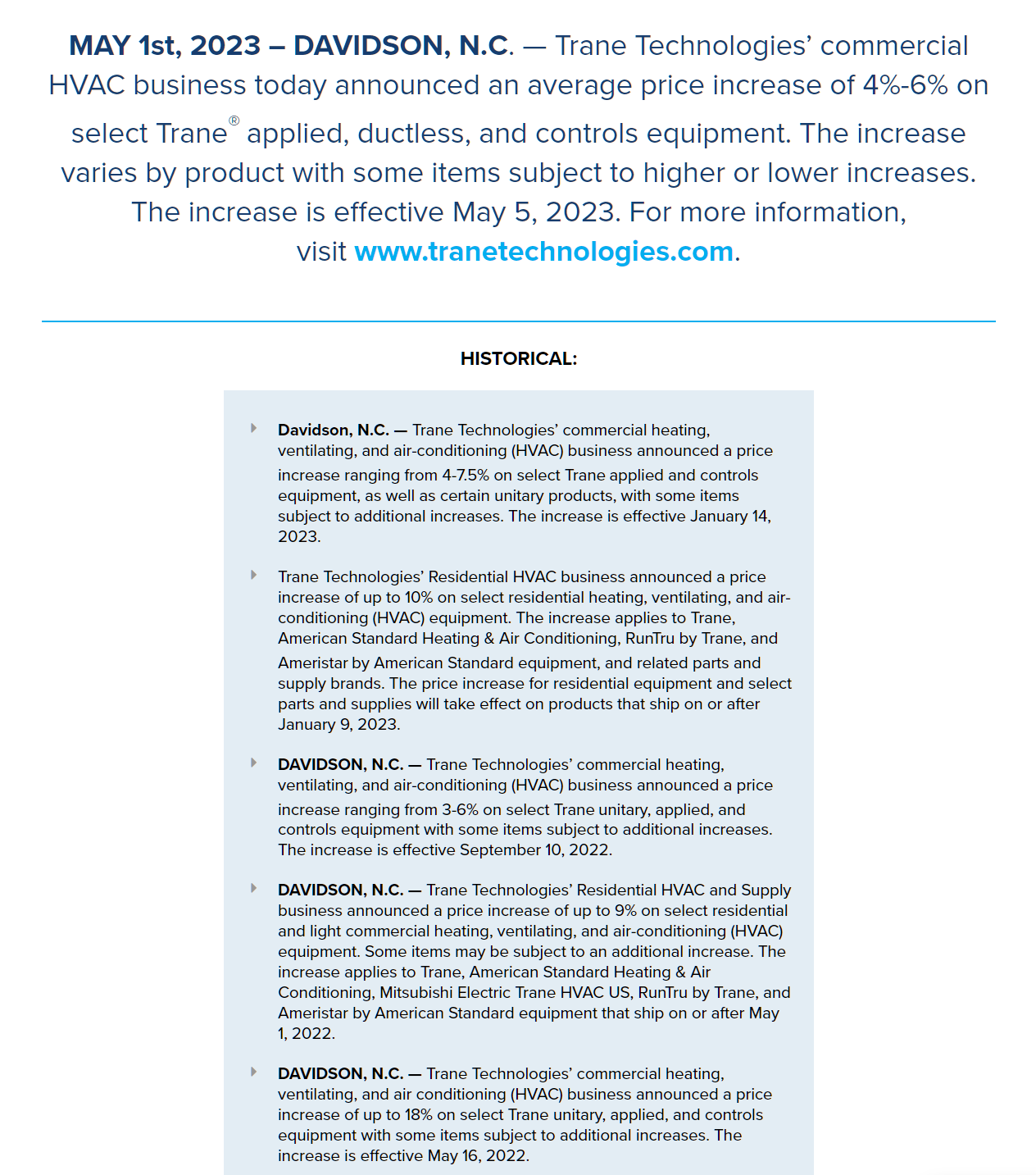

For the HVAC inflation that does make it into CPI, here’s a tracker page from a contractor (the Trane section because that’s what came with our house). The prices went up about 5% in May after going up 10% in January after going up about 4% in September 2022 after going up 9-18% in May 2022….

Related:

- more than 20 percent raise for streaming video from Disney (WSJ, yesterday)

- “Price hikes loom for consumers with the loss of Yellow trucking” (NBC, two days ago): After the shipping giant filed for bankruptcy, its competitors have already indicated they will not match its low-cost pricing. The U.S. just lost as much as 15% of its small-batch trucking capacity — and consumers are likely to feel the effects in higher prices as the holiday season rolls around.

New small aircraft prices have been going up dramatically for a very long time. The number of sales is very small, Cirrus, the largest manufacturer of piston airplanes, sold just a few hundred last year (https://cirrusaircraft.com/story/cirrus-aircraft-delivers-record-year-and-invests-in-innovation/). Demand for those new airplanes is, in my opinion, not flexible. Manufacturers will not gain thousands of new costumers by keeping their prices lower, they just will lose profits. Also, airplanes last for a very long time. Why would someone who is not very motivated to have the last model buy a Cirrus when a 30-year-old Bonanza is available for one third of the price or less?

The small numbers also drive the scarcity of spares and the long delivery times, I think. Companies adjust production to demand. The Cirrus buyer does not have too many alternatives to Cirrus if looking for a new aircraft. I presume that delivery waiting times for Diamond are just as long (Diamond sold fewer than 200 airplanes in 2022). So, if it is profitable for a company to keep customers waiting… it will do just that. Manhattan cabinet installers use the same approach.

Perhaps the spare parts deficit is specific to Trane.

My two 17 year old Lennox compressor/AH combos run just fine without any interaction with HVAC contractors. I had to replace a contactor (relay) on one of the compressors when it got stuck, but that’s about it (~$30). Twice a year, I spray the AH evaporator with Nu-Calgon and vacuum the drain lines from outside. Both operations take about half an hour.

https://www.amazon.com/Nu-Calgon-4171-75-Rinse-Evaporator-Cleaner/dp/B00DM8KQ3I?source=ps-sl-shoppingads-lpcontext&ref_=fplfs&smid=ATVPDKIKX0DER&th=1

I’d like to replace the units with more economic/quieter multi stage ones but dread the interaction with the above mentioned HVAC guys. Unfortunately, the units do not want to break, so I cannot really substantiate going through this pain.

Definitely not specific to Trane. A contractor told us about a disabled 5.3-year-old Carrier system that he recently replaced due to two-month lead time for necessary parts.

I’m glad I got my AV systems installed in the not-too-distant past. Each installed in FL:

Nov. 2017: 4-Ton “Tempest,” $5700.

Sep. 2020: 2.5-Ton “Carrier,” 3-head split system, $7900.

June 2021: 2-ton “Carrier,” $6900.

Each including 10-yr parts & labor warrant. No problems so far.

from the same company.

10/31/20022 AMERICAN STANDARD 14 SEER 3 ton. — $8735

5/31/2023 AMERICAN STANDARD 14 SEER 3 ton. — $11395

https://drive.google.com/file/d/1f2Gsxu8msEfO8sUaf7U-4K50G2f-5eOz/view?usp=drive_link

https://drive.google.com/file/d/1Sol5XVBf1syphZ5VhfstU13Nxxd_YPm4/view?usp=sharing

When we installed our system, the contractor proposed a single compressor for our 2-floor house and that we could adjust temperatures by just controlling the vents. We opted for two separate systems which I believe does a better job at letting us manage temperatures on the two floors. We get the side benefit that if one of the systems goes out of service that at least one floor of the house remains comfortable. I would not want to live with a single system for 2 months but I think I would do it instead of replacing the whole system.