Why don’t cars monitor 12V battery condition and suggest replacement before failure to start?

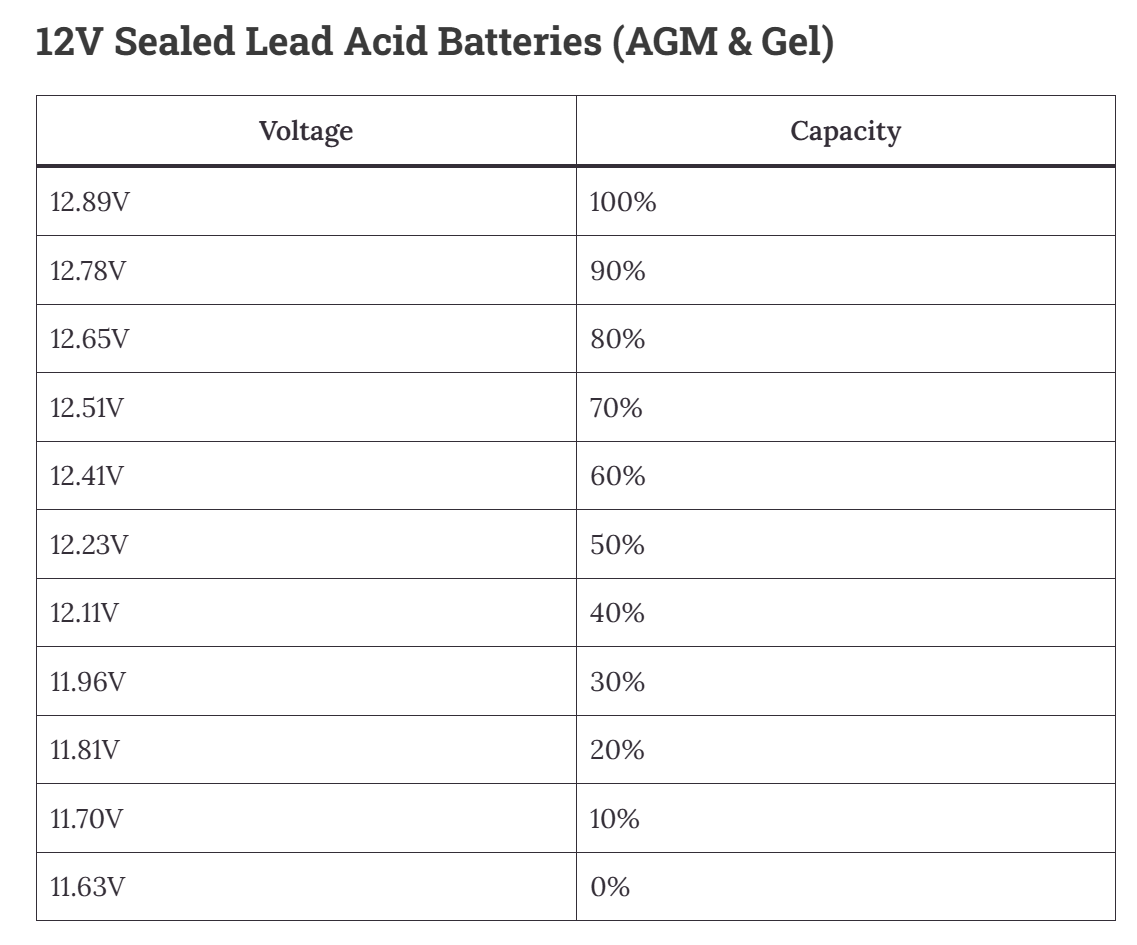

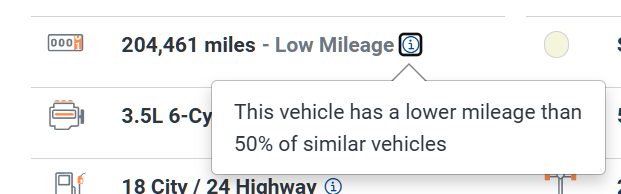

I’m not sure what caused our rented-from-Sixt Mercedes E 300de to fail and refuse to start even with a jump, but I am suspecting 12V battery health. The battery measured 12V on the tow truck guy’s multimeter, which sounds good for a 12V battery, but the chart below (source) says 12.4 is more of a practical resting minimum:

Today’s question is why cars don’t all come standard with battery health warnings, similar to the warnings regarding when it is time to change the oil.

- The car knows the battery voltage before start and after engine/generator shutdown.

- The car knows how long the last trip was (i.e., duration of most recent charge).

- The car knows how long it was sitting since the last trip (i.e., expected voltage drop from self-discharge).

- The car knows roughly how hot it has been (maybe use the temperature at startup for this and apply it to the sitting period and, if refinement is desired, tweak for the time of day).

If the car sees consistently lower-than-expected voltages, shouldn’t it flash a “replace battery ASAP” message to the owner?

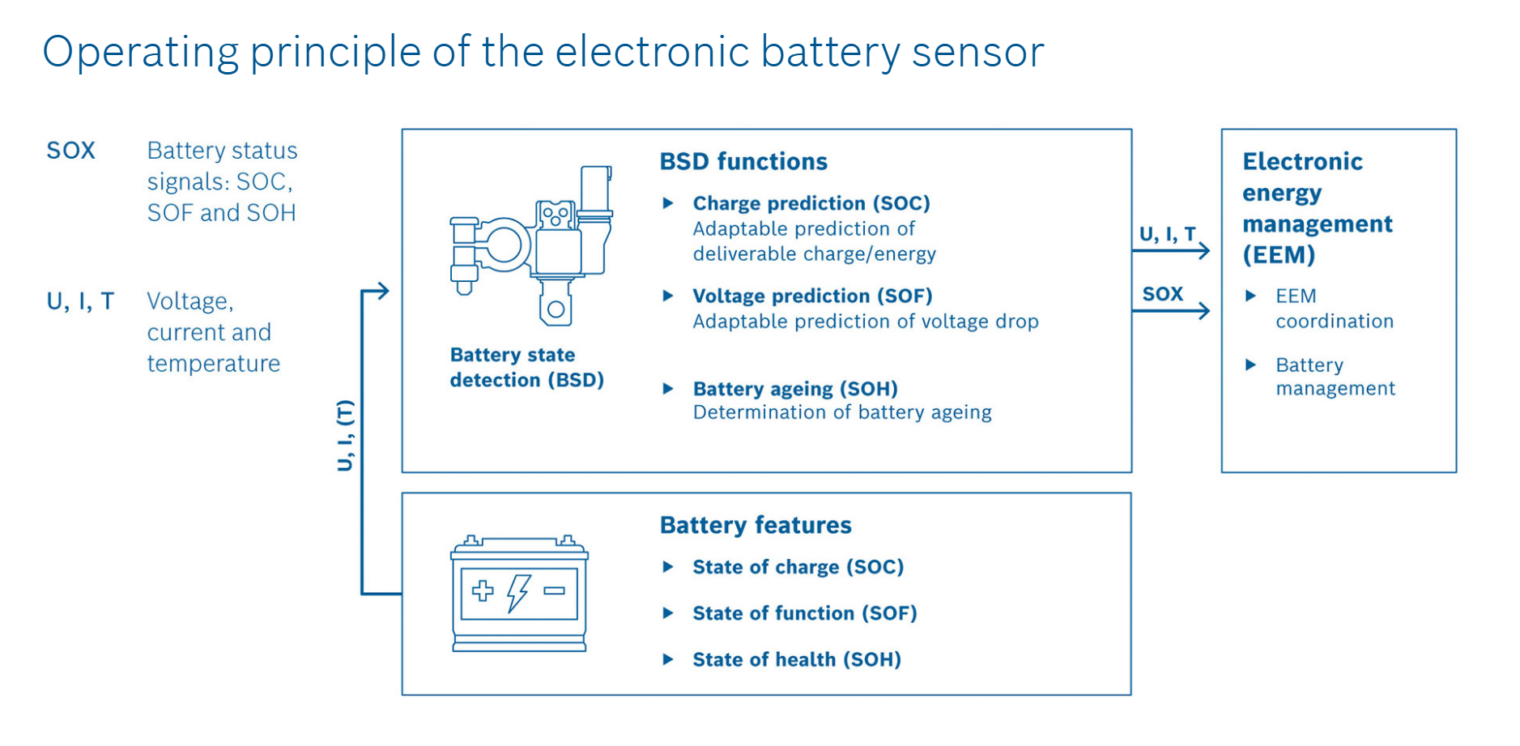

Bosch seems to have a product that tries to do this, but I haven’t seen it in action:

I’m not sure why the Bosch hardware is needed when the car already has voltage and outside temperature sensors, plus a clock.

Our dead Mercedes displayed a “low battery” warning, but only after the total failure. It also said “towing not permitted” (what is the alternative if the car won’t start?) and “See Owner’s Manual” (we weren’t supplied with one):

Ford says that an owner should come to the dealership after he/she/ze/they “Constantly experience charging or electrical system problems” or “Experience trouble or difficulty getting your engine to start”. Why is this the best that modern electronics and software can do?

Full post, including comments