No financial reward for the Covid Righteous (Metropolitan Opera)

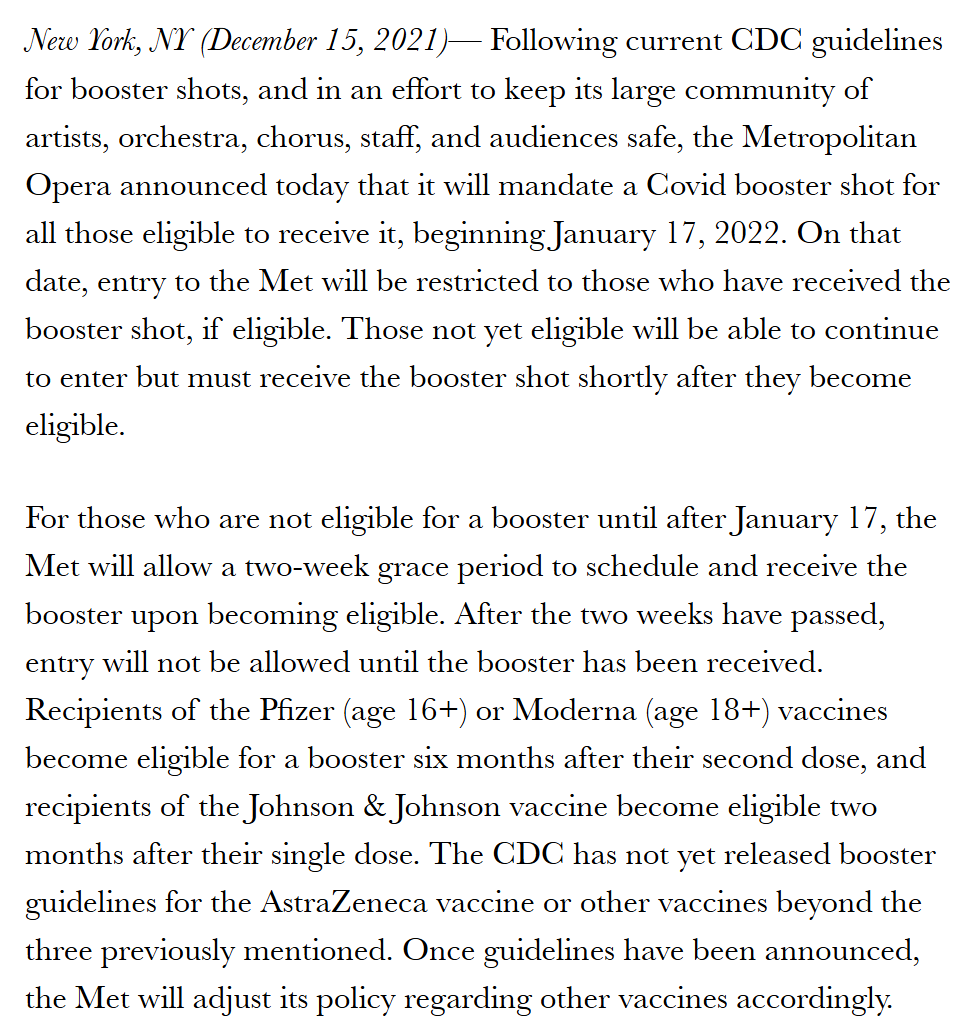

The Metropolitan Opera celebrated and followed the Science, meekly closing their doors and breaking their audience of the habit of buying tickets and attending live opera. They demanded vaccine papers when the Met was finally reopened in 2022:

The opera nerds transformed themselves into Science nerds:

The decision was made in consultation with the Met’s health experts at Mount Sinai.

What was the level of confidence in the efficacy of the required three shots?

Face masks will still be required at all times inside the Met, except when eating or drinking in designated areas.

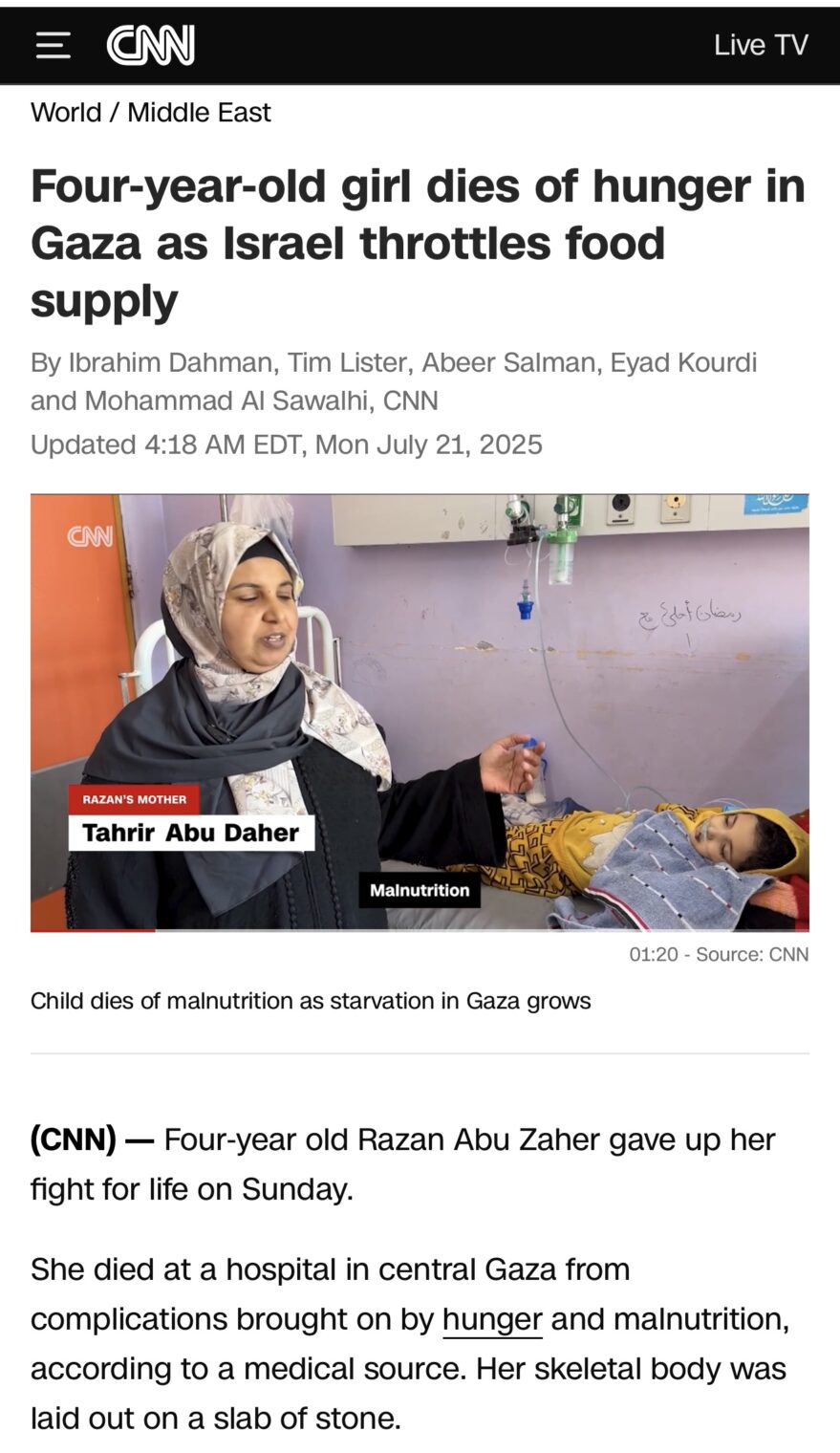

Where’s the reward for this level of righteousness? For giving up more than 1.5 years of revenue plus whatever revenue they might have obtained from the 16-year-olds they turned away for having only two COVID-19 shots rather than three?

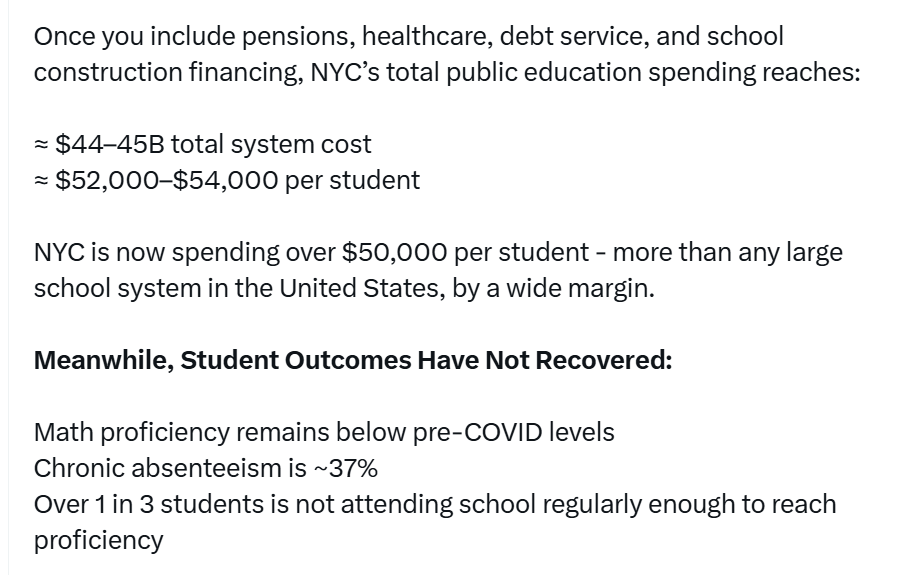

“Despite Drastic Financial Steps, Met Opera Turns to Layoffs and Cuts” (New York Times, January 20, 2026):

The largest performing arts organization in the country will lay off workers, cut salaries and reduce its offerings. It may also sell its Chagall murals that are valued at $55 million.

Over the past five years, the Metropolitan Opera has drained money from its endowment, entered a still-tentative $200 million deal with Saudi Arabia and cut back its performance schedule as it struggled to bring stability to an institution hammered by the coronavirus pandemic.

As part of the latest cuts, the Met will reduce its next season to 17 productions, from 18. (Before the pandemic, it programmed about 25 per season.)

Since 2022, the company has drawn $120 million from its $217.5 million endowment, an unorthodox and risky move that arts executives said was a sign of the depth of the Met’s financial problems.

We know that God loves lockdowns and Scientists. Why hasn’t She rewarded the Met with financial prosperity?

(Shouldn’t we be bullish in the long-run prospects for the Met, though? If the AI and Robotics age gives Americans more leisure time and owners of capital more money that should increase the number of people with the time and money necessary to attend a four-hour opera experience at the Met.)

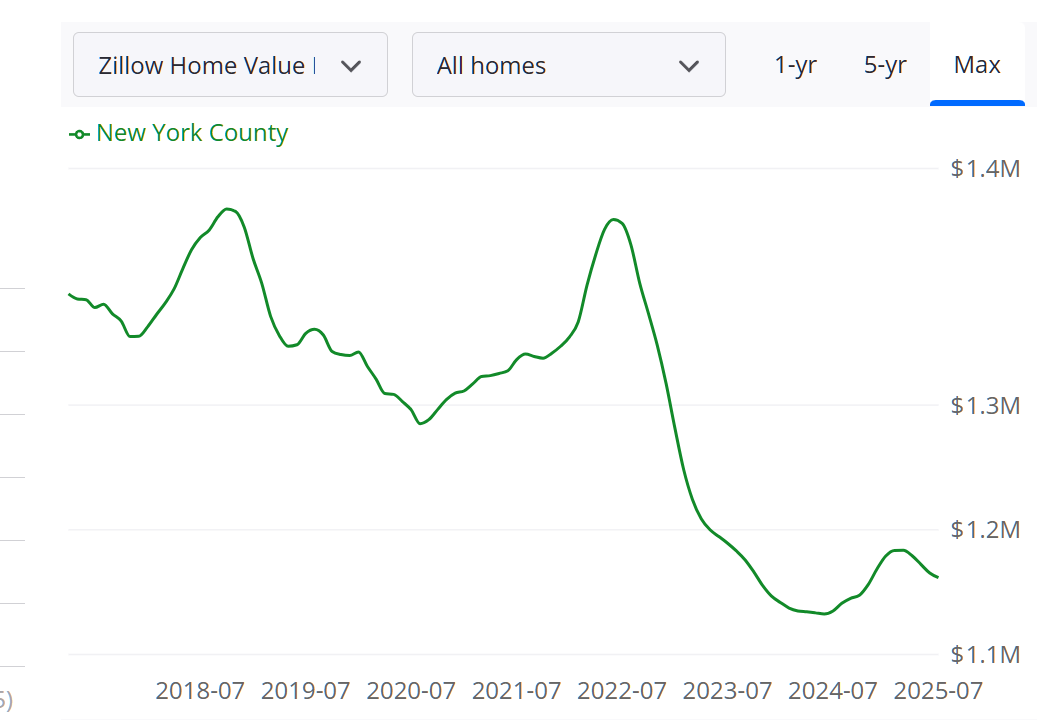

Meanwhile, among the Deplorables where forcing people to accept Covid injections is illegal… “Wells Fargo moves wealth-management unit to Palm Beach, joining Florida rush” (New York Post):

The San Francisco-based bank signed a lease with Related Ross – run by real estate mogul Stephen Ross – to rent 50,000 square feet at the One Flagler office building, wealth chief Barry Sommers told Bloomberg.

It’s a significant move for the wealth department, which last year generated $16 billion in revenue, or roughly a fifth of the bank’s total revenue, and has about 100 of its senior executives, Sommers added.

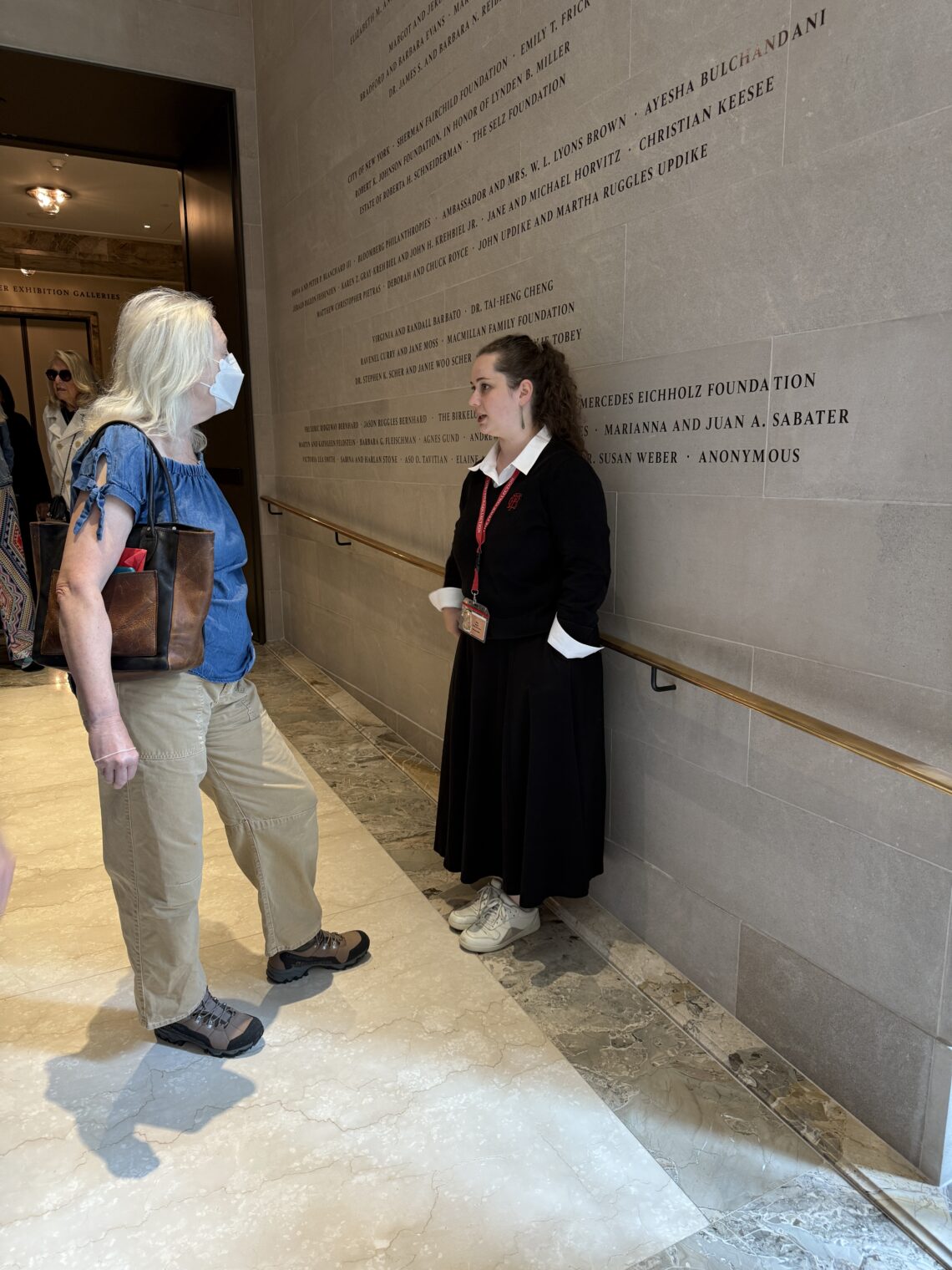

Loosely related… “Met Museum Employees Vote to Unionize” (NYT, January 16, 2026):

Full post, including commentsEmployees voted 542 to 172 in favor of joining Local 2110 of the United Automobile Workers, a driving force in the unionization of New York arts organizations that has spent the past five years quietly laying the groundwork for this vote. The bargaining unit includes employees from a variety of departments including curatorial, conservation, education and retail.