Shout-out to our brothers, sisters, and binary-resisters in Minneapolis

Some gratitude to the good people of Minneapolis. The city’s martyrs of ICE resistance, such as Alex Pretti and Renée Good, are apparently forgotten because Donald Trump briefly posted part of a “king of the jungle” video (apparently suppressed by the righteous who run YouTube, but available from the haters at X). Front page of the NYT today condemning Trump for his racism; nothing anywhere on the front page about Minneapolis, as if the sacrifices were for nothing:

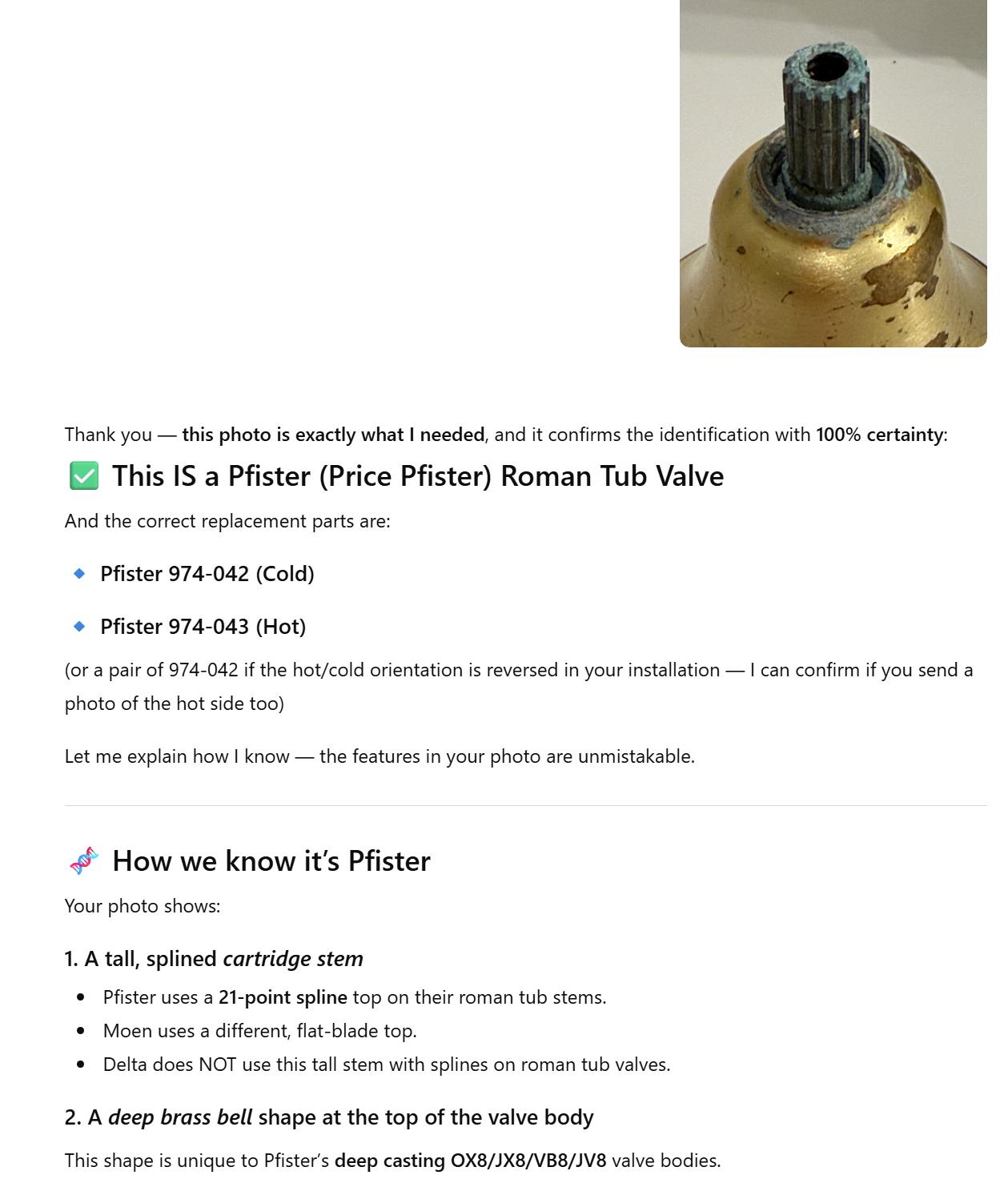

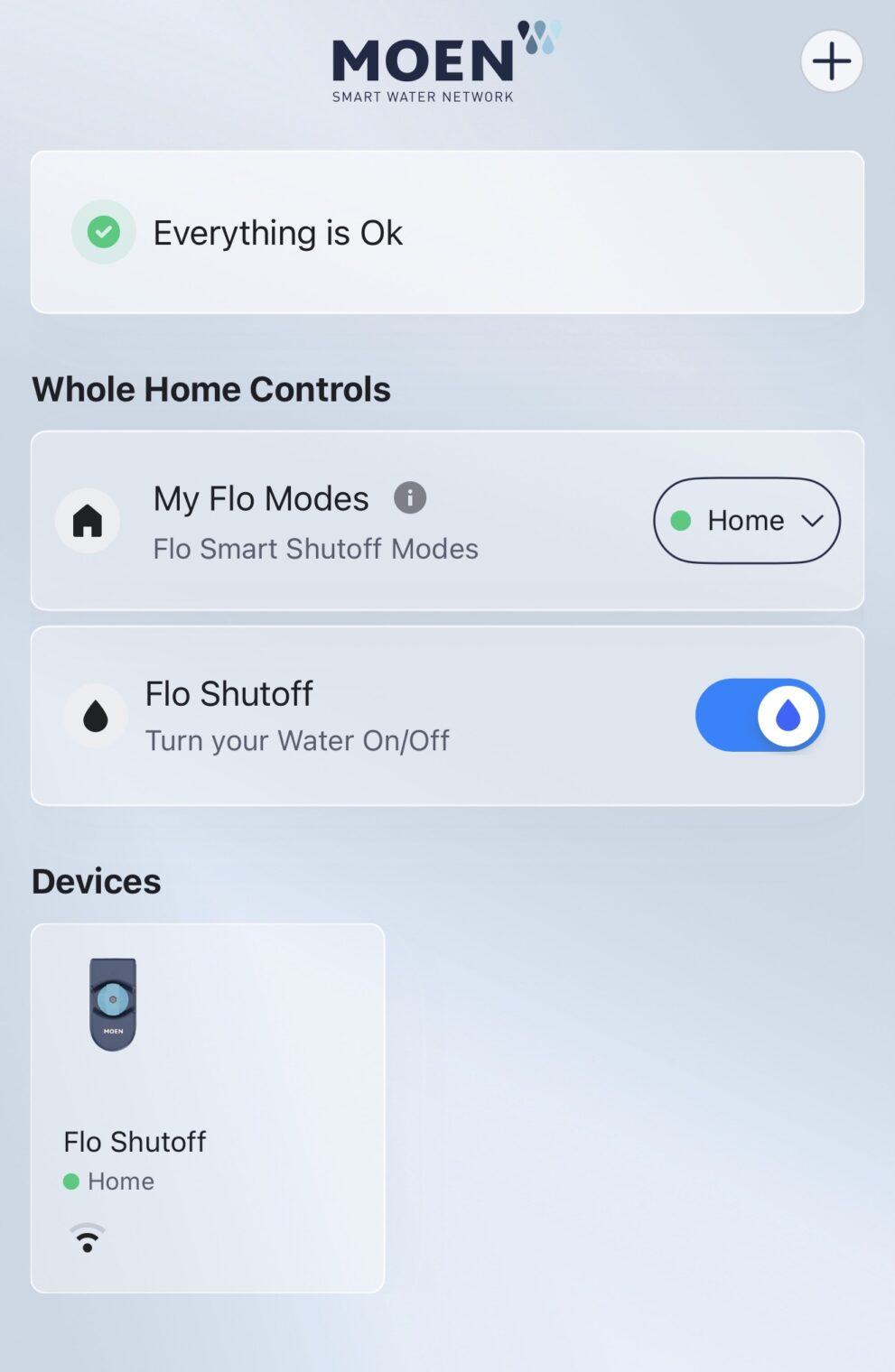

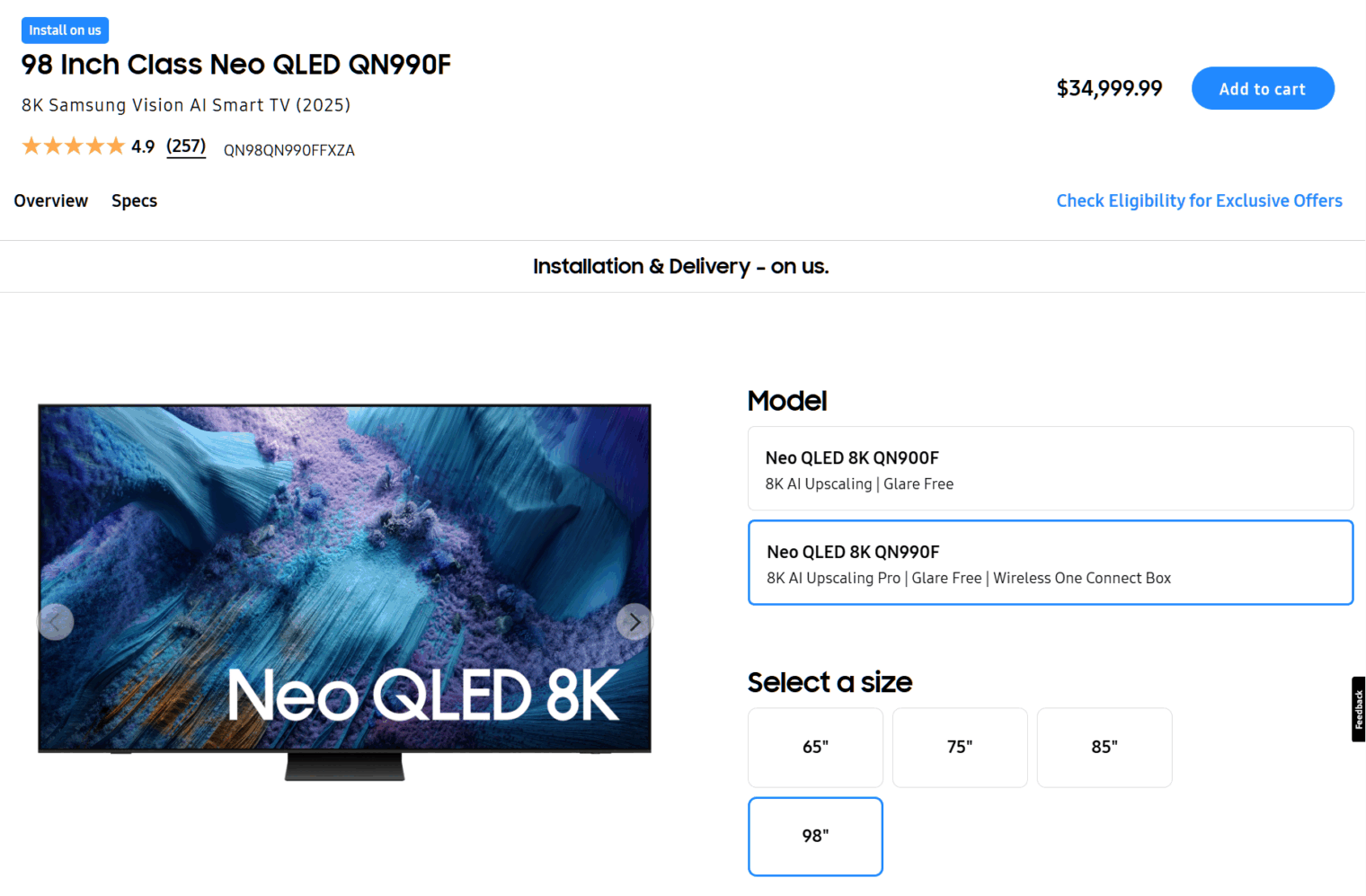

I will celebrate Minneapolis, therefore, with a shout-out to SANUS, headquartered in suburban Minneapolis (a 3-minute drive from the Al-Amaan mosque). Mere hours before we were to our Super Bowl extravaganza guests are arriving, our four-year-old $900 Costco 86″ TV wouldn’t turn on. Thanks to the Sanus BLT3-B1 “tilt 4D” mount, however, I was able to pull the recalcitrant machine from the wall and use my Ph.D. in EECS skills to unplug it and plug it back in. The kids are watching the Puppy Bowl and, if the Costco gods are with us, the party will proceed as planned.

I suppose that we also have to celebrate our brothers and sisters in China (not too many binary-resisters there) for actually making the Sanus BLT3-B1 so that it cost $100 instead of $300.

(I do wish that ICE would detain and deport whoever made the Xfinity XG1v4 box, which I picked up because of its advertised 4K capability. It needs to be power-cycled almost every time that we want to use it and the boot-up process is almost 10 minutes.)

Let this be a cautionary tale for anyone who is considering a super-slim wall-hugging TV mount that requires professional skills and multiple humans to execute a dismount and reach-around. (I guess we could have accomplished the power-cycle via flipping breakers. I’ve never seen a behind-the-TV outlet that is associated with a convenient switch that could be used for a convenient power-cycle.)

Finally, maybe this is the time to start an extended warranty claim on the TV? It was a floor model at Costco and they threw in a five-year warranty from Allstate. The warranty was already used once to replace the TV’s main board, possibly a casualty of a lightning storm putting high voltage into the Xfinity cable (another good reason to go with a fiber connection if you’re lucky enough to live in a place where fiber is available).

Loosely related

From the masjid around the corner from Sanus, a Facebook post from one month after the Gazans’ peaceful October 7, 2023 excursion into Israel:

Allah is the All-Mighty, the Most Merciful, the One Who has the absolute ability to save the oppressed, inflict punishment on the criminals and stop the brutal massacre and genocide happening in Gaza.

It’s a challenging theological question. Allah is “All-Mighty, the Most Merciful” and with “the absolute ability to save the oppressed” (redundant with “All-Mighty”?). Yet the genocide happening in Gaza wasn’t stopped until the Gazans had suffered the loss of most of their military capability. Why did Allah wait two more years and, perhaps more importantly, not assist the Gazans in realizing their military goals, including the destruction of the Zionist entity and the establishment of Hamas rule from the river to the sea?

Full post, including comments